Drum Cooking Machines: 360° Stir-Frying, Coated Pans, and the Ultimate Noodle Stir-Fry Tool

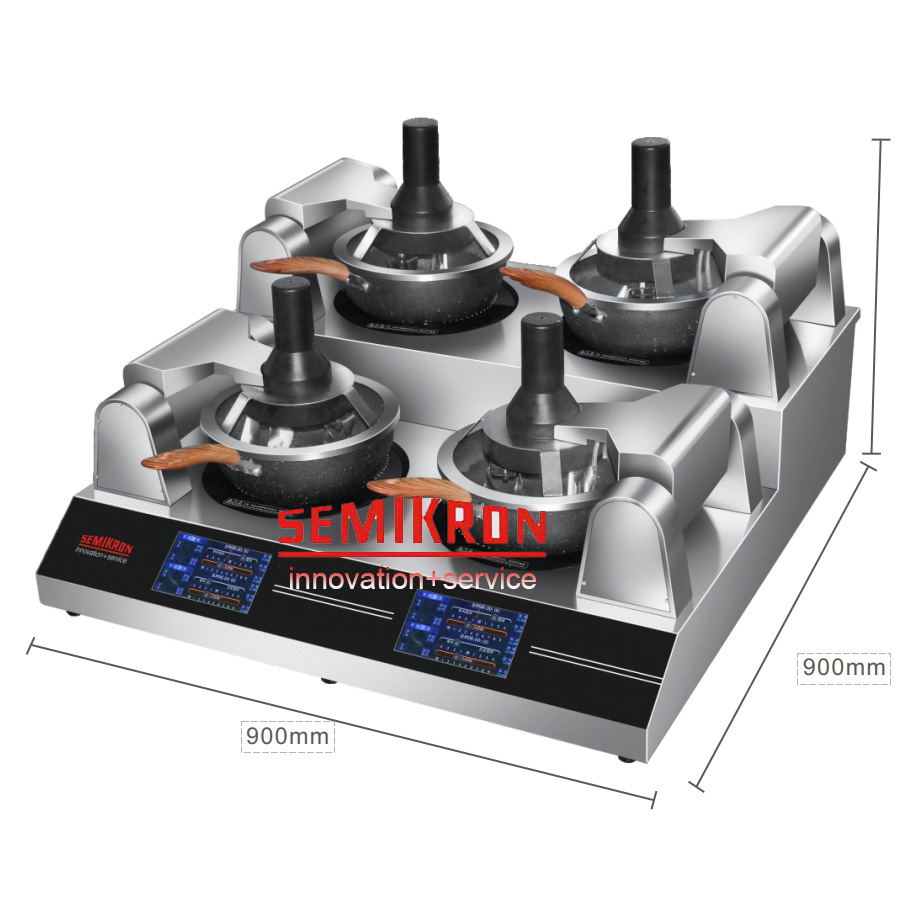

In the fast-paced world of smart cooking appliances, drum cooking machines are making waves with groundbreaking upgrades. The latest models, boasting 360° all-around stir-frying, improved coated pans, and specialized features for perfect noodle stir-fries, have become a game-changer – especially for commercial kitchens, where one person can now operate up to three machines simultaneously. This leap in efficiency and performance is reshaping how both home cooks and professional chefs approach stir-fry dishes.

360° Stir-Frying: No More Unevenly Cooked Food

Gone are the days of burnt bottoms or undercooked tops in stir-fries. The new drum cooking machines use a precision-engineered rotating system that ensures 360° coverage of ingredients. Unlike traditional models that only stir in one direction, the 360° motion mimics the hand-tossing technique of experienced chefs, evenly coating every piece of food with oil, sauce, and seasonings. “Previously, I had to stop and stir manually to avoid uneven cooking,” said Li Jia, a chef at a popular Chinese restaurant in Shanghai. “Now, with the 360° drum, I can walk away and prepare other dishes – every stir-fry comes out perfectly cooked, whether it’s vegetables, meat, or noodles.” This feature not only saves time but also reduces the risk of human error, making consistent results a daily standard.

Enhanced Coated Pans: Safety, Durability, and Easy Cleaning

Coated pans have long been a key component of drum cooking machines, but recent improvements have addressed past concerns about wear and tear. The latest non-stick coatings are made from food-grade, scratch-resistant materials that can withstand high temperatures (up to 260°C) without peeling or releasing harmful substances. Tests by independent labs show that these upgraded coated pans maintain their non-stick properties even after 1,000 uses – a 50% increase in durability compared to older versions. Additionally, the smooth surface makes cleaning a breeze: most models only require a quick wipe with a damp cloth, cutting cleaning time by over 60%. For home users, this means less hassle; for commercial kitchens, it translates to faster turnover between orders.

The “Noodle Stir-Fry King”: Tailored for Perfect Textures

Noodle stir-fries, a beloved dish worldwide, often require precise heat control and gentle stirring to avoid clumping. The new drum cooking machines rise to this challenge with specialized “noodle modes.” These modes adjust the drum speed and temperature to keep noodles separate while ensuring they absorb sauces evenly, resulting in chewy, flavorful stir-fried noodles every time. Chen Wei, a home cook in Beijing, shared her experience: “I used to struggle with sticky noodles when stir-frying at home. Now, with the noodle mode, my sesame oil noodles or chow mein turn out just like the ones from my favorite restaurant. It’s like having a professional noodle chef in my kitchen!” This feature has made the machines a hit among noodle lovers, earning them the nickname “Stir-Fry Noodle Kings.”

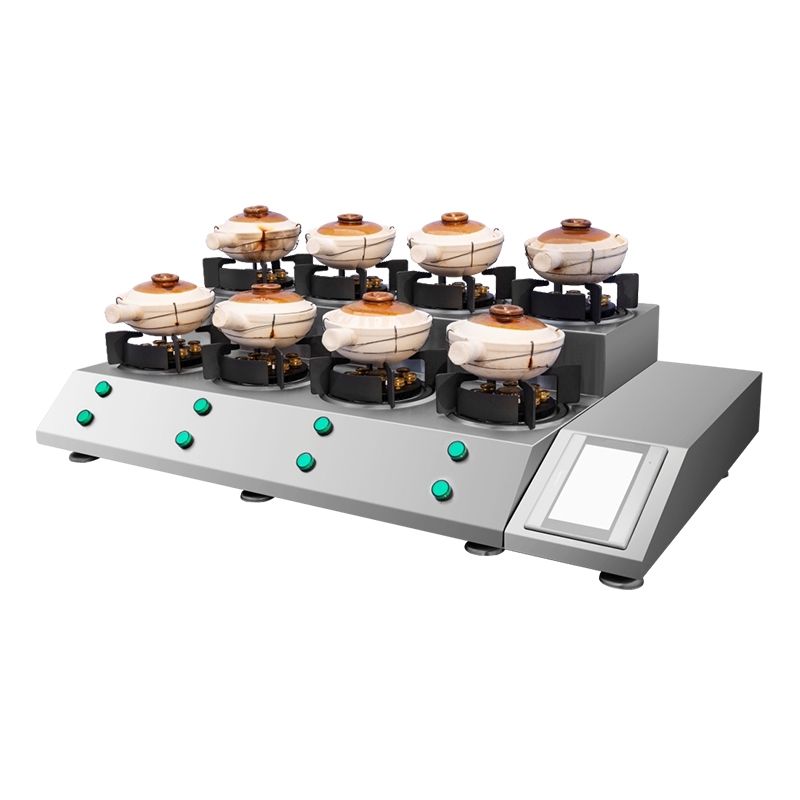

One Person, Three Machines: A Boost for Commercial Kitchens

The biggest breakthrough for commercial users is the ability to operate up to three drum cooking machines at once. Thanks to user-friendly touchscreen controls, pre-programmed recipes, and real-time temperature monitoring, a single chef can manage multiple machines without sacrificing quality.

At a busy food court in Guangzhou, this efficiency has transformed operations. “Before, we needed three chefs to handle our stir-fry stations,” said Wang Tao, the manager. “Now, one chef runs three drum machines, and we’ve increased our output by 40% while cutting labor costs. It’s been a lifesaver during peak hours.” This level of efficiency is also attracting attention from international markets, with restaurants in Southeast Asia and North America already placing bulk orders.