Automatic Noodle Making Machine Signals a New Era in Food Technology

In a world where efficiency, hygiene, and consistency are increasingly valued in the food industry, the launch of the automatic noodle making machine is drawing significant attention. This innovative device, designed to streamline the preparation of one of the world’s most beloved staple foods, represents a new chapter in the intersection of culinary tradition and modern technology.

Tradition Meets Innovation

For centuries, noodles have been an integral part of Asian cuisine and have since found a permanent place on tables worldwide. Traditionally, the process of making noodles by hand required time, effort, and skilled craftsmanship. While handmade noodles carry cultural and artisanal value, they are not always practical for high-demand restaurants or large-scale production.

The automatic noodle making machine addresses this challenge by combining tradition with technology. It is designed to replicate the texture and taste of freshly hand-pulled noodles while eliminating the inefficiencies of manual labor.

How the Machine Works

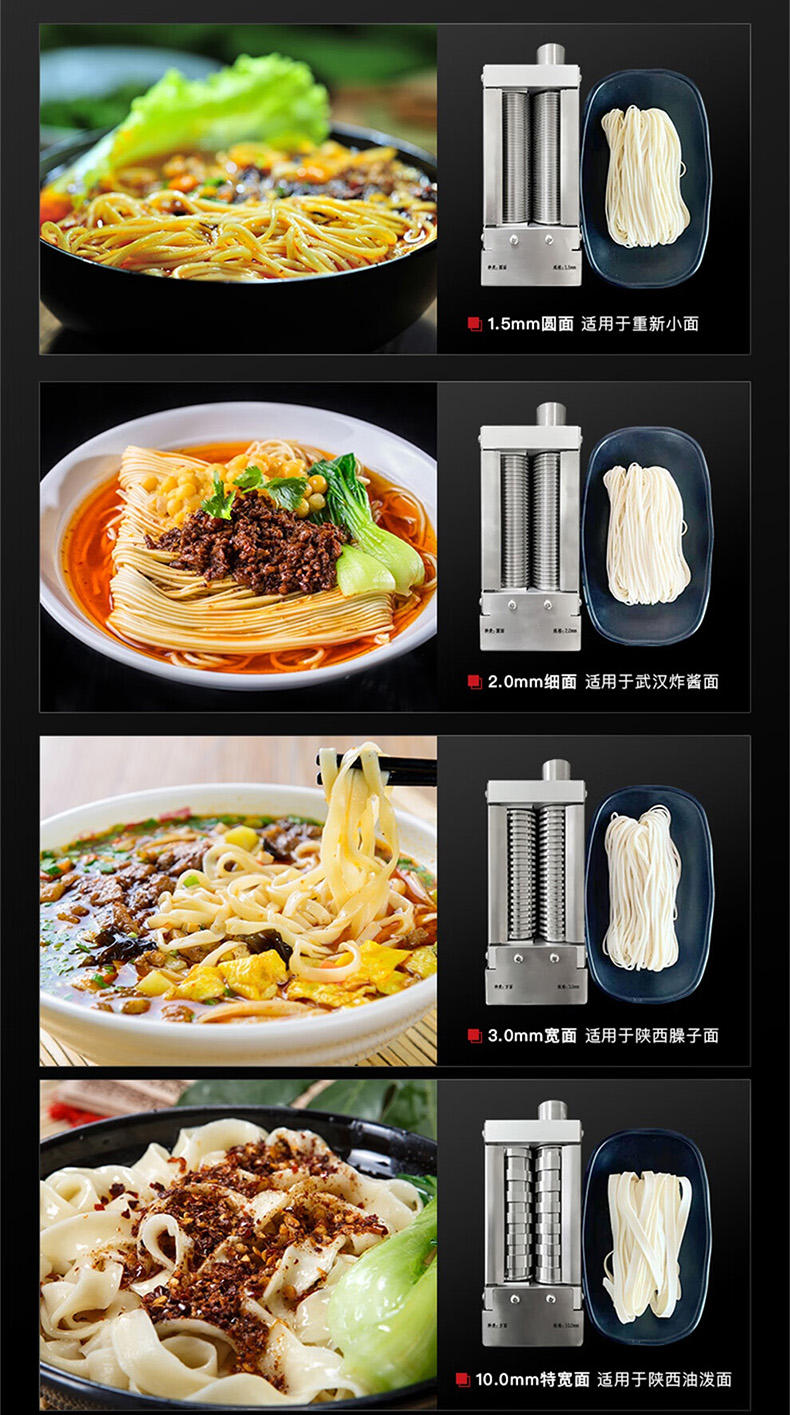

Equipped with advanced motors, precision rollers, and programmable settings, the automatic noodle making machine automates every step—from mixing the flour and water, kneading the dough, to pressing and cutting noodles into uniform strands. Some models even allow customization of noodle thickness, width, and shape, catering to various culinary styles such as ramen, spaghetti, soba, or flat noodles.

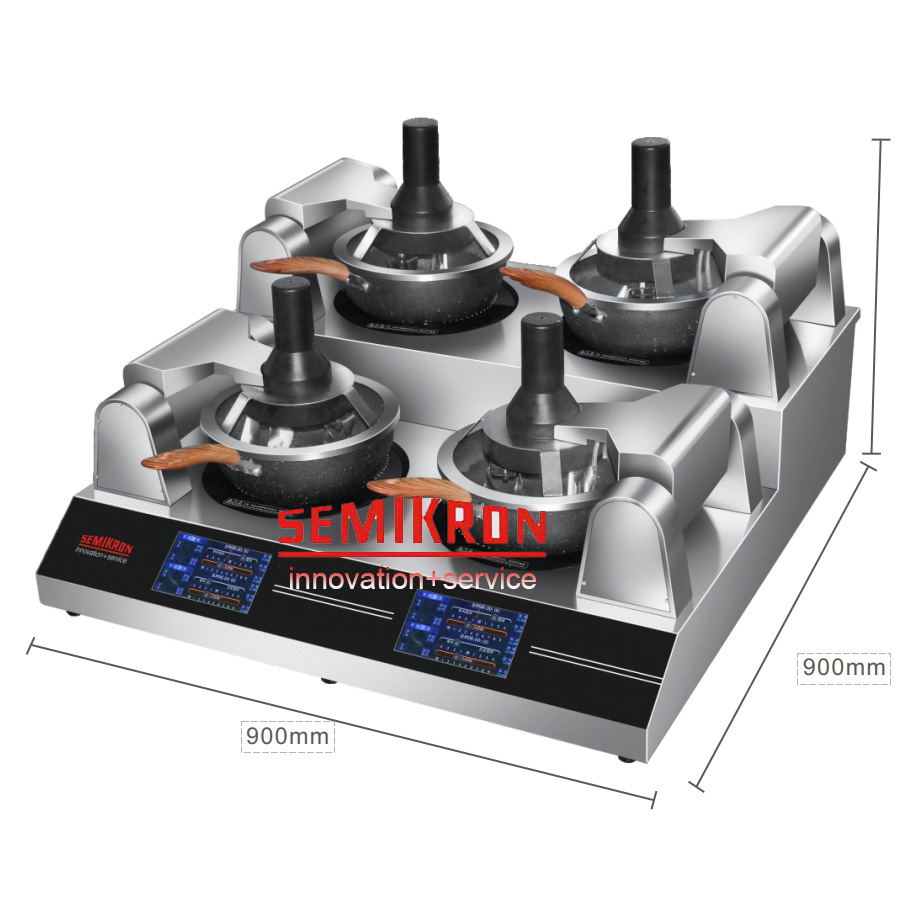

The machine’s stainless-steel build ensures hygiene, while its user-friendly digital control panel makes operation accessible even to those with little technical experience. With one touch, restaurants can produce fresh noodles in minutes, reducing preparation time dramatically.

Benefits for the Food Industry

The advantages of automatic noodle maker extend beyond convenience.

Efficiency – Restaurants and catering services can now produce large quantities of noodles in a fraction of the time.

Consistency – Every batch of noodles maintains the same texture and quality, reducing human error.

Hygiene – With a closed, automated process, the risk of contamination from handling is minimized.

Cost-saving – Businesses can lower labor costs by reducing the need for specialized noodle-making staff.

Customization – Operators can adapt recipes and noodle shapes to fit different cuisines.

Industry Reactions

Food industry experts believe the machine will become a game-changer, particularly in markets where demand for noodles is high. “This innovation allows us to keep up with customer demand without compromising on quality,” says a restaurant owner in Singapore who recently adopted the machine. “Customers can still enjoy the fresh taste they expect, but now we can serve more people faster.”

Chefs, however, hold mixed views. While some welcome the efficiency, others worry about losing the artisanal aspect of noodle-making. “Handmade noodles carry cultural value and authenticity,” one chef remarked. “But I understand that in busy restaurants, automation has its place.”

The Future of Automated Cuisine

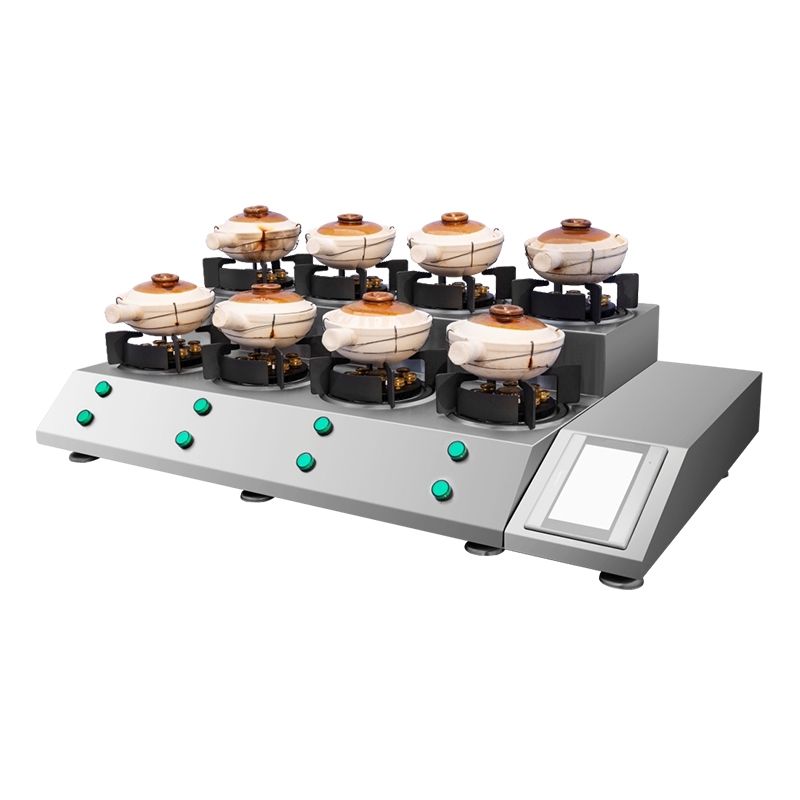

The rise of machines like the automatic noodle maker is part of a broader trend in smart kitchen technology. From robotic stir-fry machines to AI-powered coffee makers, automation is steadily transforming professional kitchens. Analysts predict that as consumer demand for fast, safe, and high-quality food continues to rise, adoption of these machines will expand not only in Asia but also in Western markets.

Manufacturers are already developing upgraded models with features like AI-based dough texture detection, cloud connectivity for recipe sharing, and even self-cleaning systems.